Automatic punched character reading system

Introduction

AlpPCR is Machine Vision's advanced solution that can recreate the three-dimensionality of marking on billets, perform accurate reading of punched characters and offer an advanced solution for product traceability.

Key features

Performance of punched character readings not only static but also on moving objects up to 1 m/s.

Deep learning functionality for recognition training on specific character types.

Extremely compact installation geometry.

Ease of use: does not require expertise in Machine Vision techniques.

System architecture

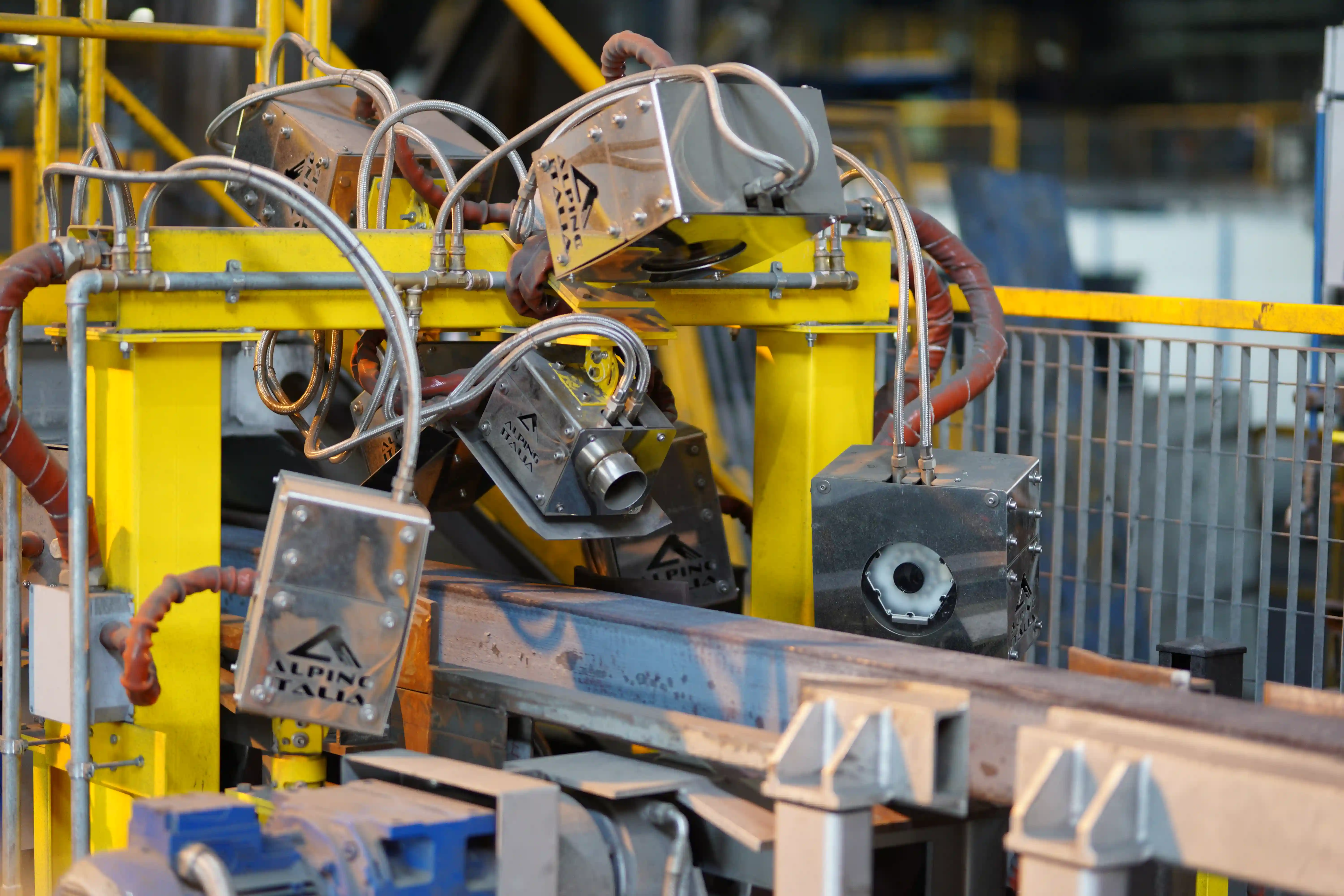

AlpPCR in its basic configuration consists of a camera, 3 illuminators, and a processing server PC for image analysis and communication with plant automation. Where it is necessary to analyze both ends of the billet because the position of the punching is not known in advance, a second set of devices can be integrated, consisting of an additional camera with respective illuminators.The aforementioned devices can be installed mechanically on the same structure, forming a gantry under which the billets to be inspected pass, or on separate supports if necessary and compatible with available installation space. Completing the field-installed devices is the interfacing electrical panel, within which the network connection (via copper or fiber optics) to the processing PC is available.

How it works

AlpPCR dialogues directly with the plant automation, with which it exchanges signals related to the area in which the billets are being handled (e.g., a firing roller way), preparing the field devices for acquisition. A presence photocell, supplied with the system, determines the correct instant at which to make the image recording, which is then processed by the processing algorithm developed by Alping Italia. By means of multispectral imaging techniques, the three-dimensional characteristics of the surface under analysis are reconstructed: within it, the depressions constituting the segments of the individual characters are identified; these portions are isolated from the disturbances and agglomerated, reconstructing the character in its entirety on which identification for decoding is finally carried out. The results of each processing are displayed on the graphical interface, available both locally and as an application with client-server architecture that can be installed on any PC connected in the same network as the processing server, where the decoded strings are superimposed on the acquired images. Contextually, the same data are also sent to the plant PLC for material tracking management. Upon request, communication to a database for data historicization can also be implemented in the system.

Technical specifications

LED Illuminators*

3÷6

* depending on system configuration, reading on one side only or both ends.

** depending on installation space camera and illuminators can be placed on separate support structures.

*** for higher speeds preliminary verification by Alping Italia technical office required.