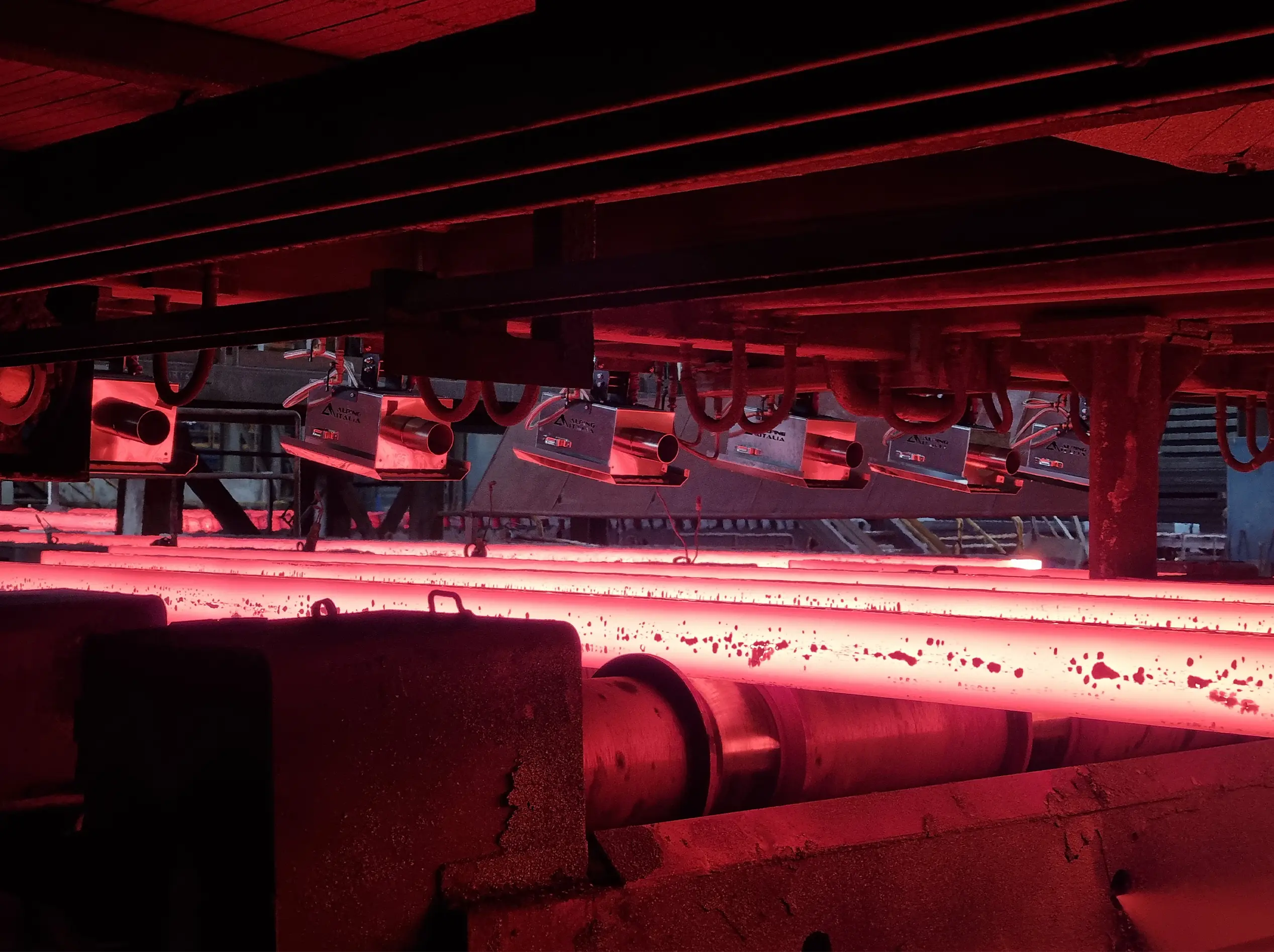

Automatic rhomboidity measurement system on billets

Introduction

AlpRMS v2 is an innovative Machine Vision-based system that can detect the presence of the characteristic rhomboid shape defect on the face of billets. It automatically calculates dimensional values, through image processing, and provides timely warnings and alarms in case of nonconformity.

Key features

Accuracy: high quality images, even on moving products

Ease of use: no Machine Vision knowledge required

Alarm reporting: non-conforming billets

Real-time communication with plant automation and level 2

Data historicization and image storage on database

Modularity: from 1 to a maximum of 6 cameras

Operational security: no specialist required in dangerous areas